Website created by PRANA

+7 905 287-21-83

pfstandart@gmail.com

PHENOLIC PAPER FOR PLYWOOD LAMINATION

Coatings for the furniture and woodworking industries

+7 905 287-21-83

pfstandart@gmail.com

All rights reserved || 2016-2020 ©

PHENOLIC PAPER FOR PLYWOOD LAMINATION

Coatings for the furniture and woodworking industries

LLC “Production company “Standard”

LLC “Production company “Standard”

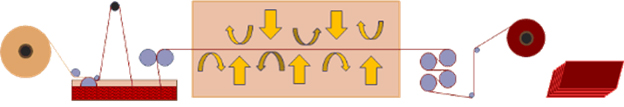

MANUFACTURING TECHNOLOGY

The impregnation process involves impregnation of various papers (decorative, Kraft paper) with special thermosetting resins (phenol-formaldehyde, melamine, etc.) and subsequent drying of the impregnated cloth to specific moisture values.

A roll of Kraft paper is installed on the unwinding device. Then, the paper web is stretched through the shaft system of the impregnation unit, where the uniformity of impregnation and the quantitative content of resin in the paper (impregnated paper) are regulated.

The paper web impregnated with resin is taken into drying chambers, where it is blown with hot air. There are 8 zones in the drying chambers, in each of them the temperature and speed of air circulation can be adjusted. In the process of drying, the necessary degree of resin condensation is achieved; the humidity of the finished product is regulated.

At the exit of the drying chambers, the paper passes through a system of cooling shafts - during refrigeration, the curing processes and reactions occurring in the paper stop.

By means of the edge-to-width trimming mechanism, the paper is cut to the desired format. Next, the paper goes either to the winding device and wound into a roll, or to the transverse self-tapping system, where it is placed in stacks of sheets of a given length.

EQUIPMENT

During the production of phenolic paper and impregnated paper, we use modern imported equipment, which allows us to create consistently high quality products:

Unwinding unit

Drying chambers with gas burners

Quality Scanner

Line for impregnation with phenolic resin by VITS Technology GmbH

Installation for impregnating solutions preparation by IFA Industrielle Wiegetechnik GmbH

Industrial controllers by SIEMENS

SCHEME OF MAIN MANUFACTURING PROCESSES:

Bath with resin

Drying chambers

Cooling shafts

Winding into a roll / Cutting into sheets